FISH PROCESSING

AUTOMATIC DE HEADING AND EVISCERATION MACHINERY

Machines designed for continuous cutting off heads and tails and evisceration of sardines or similar species. When the fish is positioned in the buckets, the machine cuts off the fish head and tail using blades and carries out evisceration using suction from a vacuum pump, then washes the fish

MANUAL DE HEADING AND EVISCERATION CONVEYOR

Designed to manually de-head, de-tail and eviscerate sardines or similar species. The fish may be fed into the system in bulk or in boxes. The system includes a conveyor to deposit the already cut and eviscerated fish and thus feed the packing system and waste collection conveyor.

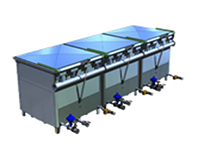

COOKING BLANCHER

Designed to cook fish (fresh, frozen or thawed) in water or brine. Constructed for various capacities, according to production requirements. Fitted with grease exit with water spray heads to collect the cooking grease for recycling. Hydraulic unit with hydraulic cylinder for opening the cover. Automatic water/brine temperature control with sensor and set-point temperature selector.

CLEANING SYSTEM

For cleaning the cooked product, elimination of skin, bones and dark parts of the fish, for subsequent feeding of the product to the tuna canning machines. The number of operators per system is established according to the required production and since it is a modular system, it can be expanded in accordance with needs. It includes individual tables or one long table, with ergonomic chairs (rotating and height adjustable), footrests and waste collection at each work station. Constructed with Cardan conveyors in closed circuits without return, producing an open, easy-to-clean system.

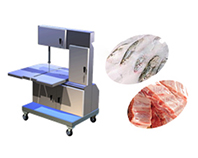

FISH CUTTING SAW

Machine designed and manufactured for cutting fresh or frozen products, with or without bones. Available in different cutting widths (400 or 700 mm) and adjustable height using a guide. Maximum cutting height is 500 mm.

FISH BLOCK MAKER

The fish is positioned on conveyors by a transfer system, it fills molds that have been previously inserted in plastic bags, which then pass through vacuum, sealing and freezing. It is versatile because it can be adapted to different block types. Considerable labor reduction, increased production, accurate weights and better end-product quality, with practically no crumb production. 500 mm.

AUTOMATIC FISH PACKING MACHINE

Designed for automatic tuna packing. The maximum machine speeds may range from 300 cans per minute Highly versatile machine that has electronic adjustment of the filling weight via the machine tactile screen without any need for mechanical changes.

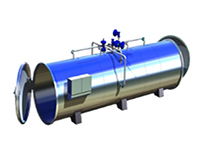

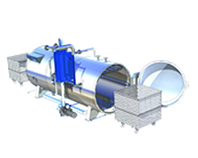

TUNA COOKER

Cooker designed for automatic and programmed cooking of tuna species or similar fish, steam cooking with subsequent cooling by internal water spry heads and natural vacuum created by steam condensation. Available in various diameters (1,500 mm or 2,000 mm) and different capacities to satisfy the demands of any production. It is fitted with an automatic controller/programmer, with capacity for various cooking programmes, ambient temperature sensors and other temperature sensors in the fish spines.

AUTOMATIC SARDINE AND SMALL FISH PACKING MACHINE

A machine designed to perform the automatic de-heading, evisceration, washing and packing of sardines or similar species. Available in various formats, attaining speeds of 200 cans per minute (according to fish size and format), with fourteen to sixteen operators. When the fish is positioned in the buckets, the machine cuts off the fish head and tail using blades and carries out evisceration using suction from a vacuum pump, then washes the fish and employs a mechanical system to transfer the fish to the can, leaving it ready for cooking.

SARDINE COOKING AND DRYING MACHINE

Machine designed for cooking and drying, if required, the fish, already packed in cans. The main feature of this machine is that the fish is cooked already packed in the upside down cans, thus allowing the grease and water to drain away during the cooking process and also fish drying, in order to produce an end product having better quality, presence and flavor. In this cooker, the cans are automatically loaded in the grilles, which are then automatically rotated prior to entering the cooking area in order to position the cans upside down and they are automatically rotated again before unloading the grilles, all of which is performed by mechanical movements without any operator intervention.

MANUAL PACKING CONVEYORS

The system where the operators receive the fish and cans and then pack them. Packing may be continuous, intermittent or static.

CONTINUOUS BRINGING MACHINE

Machine designed for the continuous brining of sardines. Constructed in stainless steel AISI-316. Available in different sizes, depending on the needed capacity.

CONTINUOUS OILER OR SAUCE APPLICATOR

Designed to add oil or sauces, by curtain or overflow, to the containers before they are closed. Constructed with one or more dispensing units depending on required production and format. The surplus oil or sauce is filtered prior to returning to the accumulation tank from which it is pumped back to the dispensing units.When dispensing sauces, a stirrer is installed in the accumulation tank, which maintains the sauce mixture.

CAN WASHING MACHINE

Designed to wash cans with pressurized water from the machine tank. Its design enables the water-oil emulsion to be continually recovered. Subsequently, the oil can be recovered by separating it from the water with a centrifuge pump. Washing is performed with hot pressurized water and with the can positioned laterally to achieve greater free washing surface.

AUTOMATIC OR SEMI-AUTOMATIC CAN SEAMING MACHINES

Machine performs double seaming Which closes the can hermetically. Speed can be from 10 cans per minute to 350 cans per minute. This machine can be integrated to automatic filling conveyor

CAN RETORT

Designed to sterilize all types of conserved foods in sealed cans, with temperature and pressure control. Steam sterilization with water spray heads with over-pressure.. Available in various diameters (1,500 mm or 1,380 mm) and different capacities to satisfy the demands of any production.

WASHER AND DRYER FOR CANS

Designed to wash and dry the cans after sterilization. Washing is performed with hot pressurized water and with the can positioned laterally to achieve greater free washing surface. Drying is also performed with can laterally positioned and with our own design of blower blades, first connected to a compressor then to a high-capacity blower.

FISH VACUUM DYING MACHINE

Under the condition of fully vacuum design, it only fills with few dyeing gas to achieve desired dyeing effect. Not only it can offer an attractive appearance of fish slice, but also it can improve product's freshness.

VACUUM TUMBLER

This machine is for shortening pickling time while upgrading product freshness, increasing water content in pickles, maintaining tenderness and then improving product quality. This unit conforms to HACCP, easy to clean. It can rotate forward / reverse and adjust the speed. The time of vacuum, exhaust pressure and total time can be set as desired to fit various products' need. Easy and safe to discharge.

HEAVY DUTY VACUUM PACKING MACHINE

Made of stainless steel, in line with food hygiene and safety. Wheels are with brake. Waterproof digital display panel. Programmable for data up to 10 set-ups. Each group can operate individually. Electronic components are protected by waterproof electrical box. Durable working table surface. The vacuum cover's height can be based on the product's thickness. Providing flat plates to slightly adjust the height of packaging. Pneumatic auto lifting arms for lid closing and opening system to improve packaging capacity.

THERMOFORM FILLING AND PACKING MACHINE

Durable transmission chain can clip the film more than 2 million times. Servo motor provides precise and fast forward. Multi-lingual PLC touch screen. Able to work with automatic filling machine, date injecting, date thermal printing, film easy to tear, water cooling machine, etc. Simple, easy change over for die sets; Custom die size. Automatic notice for insufficient film supply. High-speed production can reduce considerable labor costs. It can be used to package powder, paste, solid and liquid materials. We also offer a variety of options for this machine.

FLAKE ICE MAKING MACHINES

supply flake ice making machines from 50kg per hour tropical ice making models to fully automatic containerized ice making plants

- Available with daily capacities starting at 250kg

- Guaranteed ice production

- Individual installation

- Low noise level

- Perfectly hygienic ice

PRAWNS/ SHRIMP PROCESSING PLANTS

We also supply shrimp de-heading, cutting , cooking and IQF freezing lines or individual equipment