CONFECTIONERY AND CANDY MAKING LINES

Batter & cream preparations

The pre-mixing equipment can be made in various sizes according to the productivity required. We offer two dedicated mixing system, one for batter and one for cream. The turbo mixer is designed to emulsify and aerate batter and cream using air, in order to achieve the desired final specific gravity. Emulsification is achieved thanks to the design and building technology of rotor and stator.

C.I.P. Unit

The C.I.P. (Cleaning in Place) unit is engineered to wash and sanitize production plants (turbo mixers) without the need of disassembling them.

Decoration before oven

With our before oven decoration technology you can personalize your products. Choose decoration color and pattern.

Baking section

Cyclothymic ovens are the best solution for sponge cake. This kind of ovens combine the power and control to perfectly bake the sponge cake while controlling the internal moisture of the product.

Sponge roller depositor

The roller depositor creates a layer of batter deposited directly on the oven belt. The batter deposit can be regulated both in width and in thickness.

Longitudinal cutter

The longitudinal cutter is made of a stainless steel shaft holding the cutting blades. The rotating blades cut the sponge cake longitudinally. The width of the cuts changes according to the final product to be made.

Syrup dosing unit

This machine is designed to dose syrup either alcohol or non-alcohol based on the sponge cake sheet after the longitudinal cutter. Syrup will give flavor and moisture to the final product.

Filling dispenser

The cream and jam dispenser are custom made according to the final product and to the final cake. The dispenser is designed to regulate the dosage homogeneously on the sponge cake. Nozzles are made in plastic resin for an easy and quick format change and cleaning.

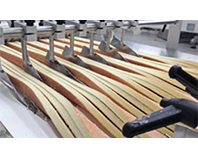

Roller tools

The sponge cake rollers are made in two versions, one for big rolls and one for mini rolls. The number of tools for the production rolls varies according to the number of rows that will be produced according to the width of the workbench. Each rolling group has a dedicated servo motor to perfectly control the rolling speed and constantly control the production.

Two layer folding tools

The tools to produce two layer cakes are made of:

- a work station with plows to overturn the cake

- a work station with lateral guides to align the two layer cakes

- a final work station to adjust the finished cake thickness.

Family size tools

Family size layer cakes are formed with a special configuration of overlaying conveyors. Each conveyor will guide the sponge cake sheet on its final position. The final size of the cake is fully customizable.

Girella workbench

The Girella forming tool is a dedicated working area to produce the girella cake. A specific roller device rolls the sheet of sponge cake transversely to the line, creating a roll wide as the deposited cake. After the rolling a specially designed tool separates the cut cakes and deposits the finished product on the conveyor.

Tri-layer cakes tools

The triple layer cakes is made with special shares and overlay conveyors.

The work phases are:

- creation of the first double layer cake with cream filling

- overlaying the first double layer on another layer of cake with cream on it

- sizing the final product

Sponge Cake Packing machines

Electronic continuous box motion Horizontal Wrapping Machine. Specific machine for modified atmosphere packaging thanks to the tight packs granted by this sealing system.

It is the most suitable flow-wrapper when: aesthetically good-looking packages with high quality side gussets and thick wrapping materials are required.

Its cantilevered frame and easy access for cleaning and maintenance, keep the vast margin of the highest hygienically standards and industrial production aspects.

Hard Candy/Lollipop depositing line

Hard/lollipop Candy depositing line is advanced equipment which can continuously produce various kinds of hard candies under a strict sanitary condition. This line can automatically produce high-quality hard candy, such as single color candy, two-color candy, crystal candy, central-filling candy, etc. The processing line is also an advanced and continuous plant for making different sizes of ball-type lollipop candies, also can make the two-color striped lollipops, and ball-type lollipop (stick adding can be done automatically). It also can make toffee candy, just to change the sugar cooking system.

Jelly Gummy Candy depositing line

We make high quality jelly candies by replacing molds and filling plates. The whole line consists of jacketed dissolving tank, jelly mass mixing and storage system, depositing machine, cooling tunnel, conveyor, sugar coating machine (optional). It is applicable for all kinds of jelly-based material, such as gelatin, pectin, carrageenan, acacia gum etc. Automated production not only save time, labor and space, but also reduce the production cost. Electrical heating system is optional.

Die forming soft milk candy production line

This production line is an advanced plant for making different types of soft candy, such as milk soft candy, center-filled milk candy, center-filed toffee candy, eclairs etc.

Automatic control for vacuum cooking and aeration mixing process;

An unique design of aeration mixing system guarantees a high quality product;

Synchronized control for central-filling, extruding and rope sizing;

Chain style die for different shapes of candy;

Steel cooling belt is optional for better cooling effect;

Pulling machine is optional for pulled (aerated) candy requirement.

Marshmallows production line

We split the marshmallow stream in four and into each we inject colors and flavors. Those four colored streams are pumped to the rotating extrusion manifold. The manifold twists the ropes while extruding them on a starch bed on the conveyor belt. The starch prevents the sticking of marshmallow to the conveyor. On top of the ropes of marshmallow, a full second layer of starch is deposited to easily guillotine-cut the ropes at the right size. The pieces fall in a vibrating sieve and excess starch is collected to be re-used. The finished product is then transferred to the curing room before packaging

Automatic hard candy wrapping machine

Using the most high-end technology, touch screen automatic computer control, servo motor system, can adjust the various sizes of packaging quickly and easily;

Multi-zone temperature control device, the touch screen can be arbitrarily set, good packaging and high- quality sealing to ensure product good quality packaging;

High filling efficiency of the feeding plate (plate diameter 1050 mm); High-speed automatic splice; Mechanical failure automatic alarm display, easy operation and easy maintenance.

With up to 1,200 candies/min

Double twist packing machines

Double Twist Packaging Machine is designed for high speed packing hard candy, milk candy & chocolate into double twist style. The machine wrapping speed up to 550 per minute. Machine of modern design, easy to clean and easy for maintenance. Fitted with double brush feed plate system, double paper feed reel holder for inner wrap or speedy changeover of reels, air assisted paper feed system

Lollipop packing machine

Lollipop Packaging Machine is designed for high speed packing lollipop into single twist style. Frequency converter for speed adjustment, PLC control system is used on the machine; Parameter setting and paper cutting adjustment is achieved by operator-machine interface. It is of the function of automatic running and compensating, twisting and healing of paper as well as parameter display during running.