FLOW WRAPPERS

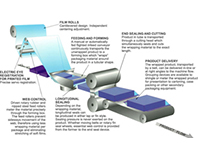

Products ranging from food and consumer products to medical devices travel horizontally in a continuous motion throughout a flow wrapper. Products are either manually or automatically placed onto an infeed conveyor which transports the product to the former. A single layer of wrapping material is fed into the machine and the former guides the material to create a tubular shape around the product. After the product has traveled through the former, the two edges of the packaging material are joined together under the center of the product. The joined edges of the material are then sealed together in either a longitudinal fin or a lap style seal. After the longitudinal seal is formed, the product is transported through rotary sealing/cutting jaws. As the cutting head rotates it simultaneously seals and cuts the front of one package and the back end of another. The finished package is then discharged from the sealing/cutting head area by a conveyor belt. The discharge conveyor carries the finished package away from the sealing and cutting area for integration with Cartoner, case packers or other secondary packaging equipment.

FLOW WRAPPING MACHINE

Automatic Flow Packaging Machines has a wide using range, suitable for packaging not only snack such as biscuit, buns, bread and cake, but also mask, electrical switches, tape, drugs, cosmetic, soap and industrial parts. This packaging machine has a wide usage and can change products quickly by simple adjustment.

MULTI RAW (FAMILY PACK) BISCUIT FLOW WRAPPING MACHINE

This machine is suitable for fast packing of the multi-row biscuit or snacks without tray.

This type machine filled up blank of these products.

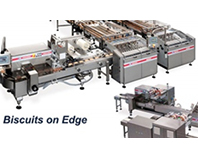

BISCUIT ON EDGE PACKING MACHINES

On-Edge Wrappers are designed for products that travel through the wrapper and are packaged standing on-edge including crackers, cookies and frozen meat patties. It is the top equipment for biscuit aggregate packaging without a holding tray.

A. FLOW FEEDERS

Products coming from the production line, narrow edge leading, in a single row at inconstant flow, are collated, gently accumulated without pressure and phased into the infeed conveyor of the flowpack machine

B. POCKET FEEDING SYSTEMS

The pocket feeding system has been specifically designed to handle products that are difficult to accumulate, feeding the pockets either singly or in multiple format to create groups in the required number and transfer them into the flow pack machine.

The products coming from the producing line at constant flow are placed longitudinally in single or multiple rows, introduced into the accumulated pockets and then transferred in the pre-established number onto the flow pack infeed conveyor.

The pocket feeding system allows Multipack packaging to be produced within a reduced space and without additional personnel.

C. ANGLE FEEDING SYSTEMS

The angle feeding system has been developed to automatically convey product flow from the production line to the packaging machine.

Two types, horizontal loaders and Vertical loaders

HORIZONTAL LOADERS

The horizontal loading, and feeding units are installed at the end of the production lines. Their function is to group into piles products in flat position such as biscuits, crackers, toast bread, etc. and to transfer these piles into the infeed conveyor of a flow-pack machine. This system allows selecting the height of the pile, from a single unit up to its maximum stable height and to transfer these piles on to the infeed conveyor of a flow-pack machine. It is possible to compensate any possible product thickness variation while the system is in operation. The modular construction of the horizontal feeder allows us to supply it in different configurations, depending on the required performance and the characteristics of the products to be handled.

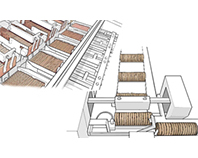

VERTICAL FEEDER

The vertical loading and feeding units are installed at the end of the production lines. Their function is to create product portions (slugs) in vertical position (on edge) such as biscuits, crackers, toast bread, etc. and to transfer them into the infeed conveyor of a flow-pack machine.

The vertical loader has been designed on a modular concept and allows configurations from a minimum of 4 channels up to a maximum of 16 channels, depending on the number of arriving product rows and on the required performances or packing capacities, in terms of number of packages per minute. The loader allows handling the continuous product flow, to convert it into portions of the desired length and to transfer them, automatically, into a flow-wrapper. The dose length regulation and thickness of each single product can be automatically changed by the operator with the machine in working mode. The vertical loader can feed either X-fold wrappers or flow pack machines thanks to the available 90 transfer. Doses can also be alternatively placed into plastic or cardboard trays.

D. VARIOUS TYPES OF ROBOTIC FEEDERS

We can provide the automatic choose pick and place systems

AUTOMATIC BREAD, BUN PACKING MACHINE

Bread Packing machine adopts the most advanced design idea of the world---complete open and suspension-arm design with servo motor controlling the speed-changing. Double vertical seal and upward clamping conveyor can guarantee tight and good packing effect. This flow packaging machinery can be equipped with one or two servo motors and timing belt instead of chains and chain wheels to satisfy our client's special request. Thus simplifies the drive system, raises the control precision, increase the packing speed and running stability and lower the noise, etc. Its open design makes it easier to maintain.

AUTOMATIC MEDICINE PACKING MACHINE

Wrapping Machine has stable performance and wide usage which can wrap several types of products such as blister packs, surgical gloves as well as syringes etc. It operates in high speed, its stability and strength. Where the contacting surface is using stainless steel,

FRUIT AND VEGETABLE PACKING MACHINE

According to the specific condition of product, optional automatic feeding system can realize unattended operation. This machine adopts closed packaging and continuous operation, so it has high efficiency and product has a line seal after packing.

INSTANT NOODLE PACKING MACHINE

Suitable for assembly packaging of the products of several blocks such as fresh noodles, ice pops, several blocks of instant noodle, several bags of milk, fans, rice vermicelli etc.

This machine adopts film bottom sending to automatically wrap, form and seal.