MILK AND MILK BASED PRODUCT FILLING

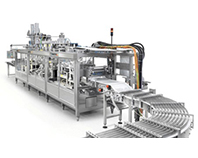

ASEPTIC CARTON FILLING MACHINES

We supply complete aseptic cartoon filling and sealing machines volumes ranging from 50 ml to 2000 ml. Machines are adopted with either simple brick packs or complex packing systems with different types of cap or straw applicators.

ASEPTIC FORM FILL AND SEAL MACHINES FOR FLEXIBLE POUCHES

The latest technology used for the THP aseptic models (actuators, automation, aseptic conditioning) meets all specifications for production rate and quality for the final product. An anti-mix connection valve on the main milk packaging line and permanent monitoring of the sterile air exhaust and the CIP/SIP system ensure sterility without the need for disassembly. The pouches are filled with sterile air injected from a buffer tank that is under constant pressure and equipped with a proportional valve and a level sensor.

PASTEURIZED MILK PACKING MACHINE

The pouches are filled with air injected from a buffer tank that is under constant pressure and equipped with a proportional valve and a level sensor.

The Machines mechanical technology means that it is operated with PISTONS, making it easy to use, with precise dosage at high speeds.

A Clean-in-Place (CIP) has been integrated into the M2500s design. All of the parts that come into contact with the product are built from stainless steel.

Its pneumatic sealing grip control and its independent electrical cabinet make its maintenance easy and inexpensive.

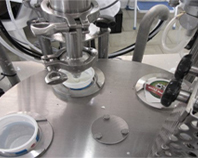

ASEPTIC FFS MACHINES FOR CUPS

The horizontal Aseptic machines use a three step packaging and filling process. Containers are thermoformed starting from a roll of multi-layer barrier plastic film (PS/EVO/PE or similar), filled with product, closed by a thermo sealed peel-able lid and then cut to the desired configuration. Special cutting tools minimize the scrap produced, which provides a significant cost saving.

The Aseptic Form-Fill-Seal machines are pre-sterilized using a combination of steam, sterile air filters and HO mist and are maintained in a sterile condition via the use of UV lamps and a Central Air Sterile Unit (CAS) which extends the shelf life of the products.

BOTTLE FILLING MACHINES

We can supply both plastic and glass filling machines with capping systems. It can be either pasteurized milk, ESL milk or UHT treated milk

CUP FILL AND SEAL MACHINES

We can supply various types of cup fill and seal machines for various types of dairy products such as yoghurt, milk, ice cream or butter. It can be pasteurized milk, cultured milk or aseptically processed milk.

We can supply slow speed rotary machines as well as high speed linear machines

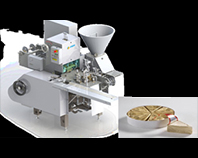

BUTTER FILLING AND WRAPPING MACHINE

Designed to fill and wrap butter, margarine, etc. into aluminum foil or parchment paper. Machine modifications covers a wide dosing range 8 1000 g and a big variety of brick sizes.

PROCESSED CHEESE FILLING AND WRAPPING MACHINE

Automatic packaging machine for foiling of processed and cream cheese with aluminum foil with or without easy opening system and labeling. It can be square shape or triangle packing.

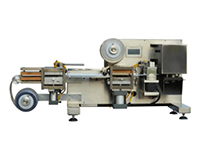

THERMO FORM FILL AND SEAL MACHINE FOR BUTTER, MARG

Thermoformer is widely used in foodstuff industry and dairy products. It is suitable for packaging of honey, cheese, jam, chocolates, butter, etc. Adopts micro-computer control system, it can automatically complete the actions of forming, filling, sealing, embossing and cutting. Adjustable drag system allows blister cards length to be set freely. Equipped with paste feeder (also suitable for liquid), it can preserve temperature that ensure the chocolate, jam, butter are discharged into blister pockets smoothly, freely and accurately