BOTTLE WASHING AND RINSING MACHINERY

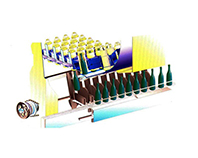

DOUBLE END WASHER

Depending on different production capacity and contact time requirements, we are able to supply double-end machine featured by 3, 4 or 5 caustic baths and complete with:

Pre-soak and warm-up treatment: the bottles are warmed up by internal and external spraying treatment which allows to reduce energy consumption; moreover, the separate contamination removal decrease the contamination load for the caustic bath and consequently the cost of the water treatment. The machine can be designed with a pre-soaking bath for the complete immersion of the bottle.

Label detachment and removal: each caustic bath is provided with a label extraction system. Propeller circulation pumps generate a current which sucks the labels out of the bottle cells and guides the labels directly toward the revolving filter bands. The filter band carries the labels out of the machine immediately after they are detached preventing their decomposition.

Post-soak treatment and cool down: bottles pass through a post-caustic jetting treatment made by 2 warm, one cold and one fresh water jetting stations which totally eliminate soak residuals. In addition each model can be designed with a water submerge bath to maintain high guarantee of soak residuals elimination also at the highest speeds.

For more details contact www.r-bardi.com

SINGLE END WASHER

Washing cycles: Can supply with different washing cycles and bottle output from 3000 bph to 80,000 bph

WORM INFEED SYSTEM

Whenever special bottles (rectangular, square, oval, etc.) are handled, it is not possible to put them on an accumulation table, consequently a worm infeed system is required.

The bottles are spaced by an infeed scroll and fed to the in load slides through a pushing device which is lined with polyethylene.

Moreover a bar will introduce the bottles into the baskets.

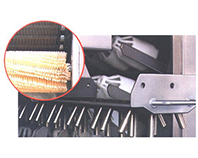

CAMS OUT FEED SYSTEM

The opening of the sliding block transfers the bottles from the baskets and places them on to the cams that, with their rotating movement, take the bottles along the slide conveyors to the discharge conveyor.

The slides and unloading cams are made of high density polyethylene to guarantee a noiseless working operation and longer life cycle. Safety devices protect all the movements

BOTTLE CELLS AND CARRIER

The design of our cells and barrier guarantees the following advantages:

Large selection of bottle cell carriers in various widths and lengths.

Optimum machine adaptation.

Easy replacement of individual cells.

Optimized wall thicknesses and cutouts in the carrier side walls which allows lighter weight, smaller surfaces, less media carryover, and less chain guide wear.

For the bottler this means energy savings of up to 30%, further reduction in water consumption and less maintenance.

LABEL REMOVAL SYSTEM

These bottle washers have a double-step label removal. In the first step, after about 40% of the total soaking time, sub-sprays remove the loose labels and the caustic flux with the floating labels is guided directly to the outload filtering conveyor extending across the machine.

In the second step, at the end of the soaking time, many sprays hit the bottles everywhere and totally remove the labels.

The caustic solution with labels is guided directly toward the revolving filtering conveyor and a rotating brush removes the labels and residuals which are sticking on it. In order to guarantee a good efficiency of this system in the long period, the nozzles are easily extractable to make a perfect internal caustic.

SELF-CLEANING NOZZLES

This spraying system consists of rotating shafts, radially drilled on each row of baskets, having a star on one end operated by a strike fixed on the basket carrying beam. This system gives a perfect synchronism and centering between sprays and bottles, even if the main chain would have to become longer during the years.

Moreover the geometrical shape of these sprays lets the water lick flirt one internal side of the bottles, after the bottom of the bottles and then the other internal sides.

For more details contact www.r-bardi.com

BOTTLE RINSER

They represent the traditional solution able to optimize the purchasing costs and are fit for the traditional rinsing treatment using water, air, steam with fixed parameters of treatment.

The spray nozzles can be fixed or penetrating in bottle by 1, 2 or 3 treatments with the "No-bottle No spray" mechanical equipment (Option).

The double opening taking pliers fit to treat very heavy bottles (2.5 kgs) without needing a neck support.

The opening and closing of the mechanical spray valve is driven by the movement of the pliers and by the the presence of the bottle in the same. The mechanical spray valves are in AISI 304 stainless steel (AISI 316 on request).

The special design of the collector allows to minimize the number of gaskets; they are certified for the food industry use (FDA certification).

The machines can be manufactured both adjustable in height with a traditional chain conveyor for glass bottles, and fixed in height with inlet and outlet air conveyor for PET bottles (neck handling).

In this case it does not exist the possibility of size change for different PET bottles having the same neck.

SEMI-AUTO GLASS JAR WASHER(BY AIR OR WATER)

The washing machine can be used for washing plastic, Glass bottles or cans with different size.

The inner water tank is made of high quality of stainless steel.

UV STERILIZER TUNNEL

This sterilizer tunnel adopts UV sterilizer bulbs to kill bacteria to make the products safe.

When products go through of the tunnel, it will be sterilized by UV bulbs and sterilizing time can be customized.

This machine is very easy to operate, electrical configuration adopts famous brand.

LINEAR RINSER / BLOWER

Linear rinser / blower is equipment suitable for cleaning inside empty containers before they are filled. The rinser / blower machines can perform, depending on the need, the blowing or washing the inside of the containers so as to ensure their complete internal cleaning.

PUR-RINSE WATERLESS CLEANING

We now offer Pur-Rinse Systems for cleaning all types of non-returnable containers. This Air-Vac technology uses high pressure ionized air as the cleaning agent, combined with a continuous vacuuming process to help remove debris. The system has built-in diagnostic features and an internal alarm function to ensure proper operation. The company believes this Pur-Rinse system improves quality, saves water, eliminates residual water in the container and eliminates microbial issues.

HOT WATER RINSER

From 2000 to 80,000 bottles per hour

For more details contact www.r-bardi.com