VEGETABLE PROCESSING

Destoners

The screw de-stoner can be used in conjunction with all root crops. The integration of this system into a processing line dramatically reduces the potential for extreme wear and tear to associated equipment further along the installation.

The rotational action raises the product allowing the water to gravitate down the side of the auger. Heavy particles with negative buoyancy remain on the bottom of the hopper. Clean product (without stones) are transported out off the upper side of the transport screw.

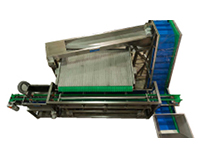

Salad and Root washers

This washer has an integrated air injection system, enabling a thorough cleaning action without damaging the product. The quantity of air can be adjusted continuously, so that a stronger or softer turbulence in the washing water can be achieved.

The out-feed belt is constructed as a dewatering belt, provided with a re-arrangement beater and a vacuum system to aid the maximum removal of free water. The air knife on the end of the belt takes care of removing all product off and out of the belt

Polishing

Rotary Brush roller consists of number of brush rollers forming an elongated drum. The drum and rollers rotate separately and have independent adjustable speed controls via a series of heavy-duty V-belts.

Access for cleaning and maintenance of the brush polisher is gained through large side doors on either side of the machine.

Centrifugal Drying Tunnels

This revolutionary new centrifuge design concept delivers the ultimate control for the drying of delicate salad leaves, standard lettuce varieties, prepared vegetables and delicate herbs. The drum has a completely smooth inner surface without a central axle or other contact parts which could directly damage the product.

The unique construction of the centrifuge minimizes product damage because of the spacious drum dimension and the controlled layer thickness of the product which eliminates product pressure during the spin cycle

Roller grader

The roller grader grades out a pre-determined undersized small pieces from a product flow. The grading size is step less adjustable.

Grading Drum

Removes small pieces from a flow of carrots after cutting or peeling. The size of the removed pieces is depending from the chosen cup size.

The air drying tunnel is the very latest in 'State of the Art' technology and is especially effective on delicate specialized baby leaves. In the drying tunnel the product is dried in an upwards directed air stream which passes through the transporting belt.

Knife peeler/ Carborundum peeler

The carborundum version the machine has a carborundum covered interior and a carborundum disc. The peeling disc can be taken out and is designed to enable the product to rotate within the machine. This allows the product to be peeled evenly around. In the knife peeling version the product is knife peeled to obtain a smooth surface. Any potential bruising and peeling losses are greatly reduced thanks to precision knife adjustment and the rubber skin inside the drum.

Onion Peeler

The basic model onion peeler. Onions are picked and positioned on the machine by hand. Onion peeling is done automatically at 60 onions per minute.

Knife Peeler

Knife peeling system for long shaped products such as carrots, salad cucumbers, etc. Totally dry peeling with low waste and a perfect smooth product surface. Worldwide well-known carrot peeler.

Vegetable cutters

By using our different vegetable cutters we can cut vegetables in to slicers, cubes, stripes as well as different shapes by using different machines. It can be a micro cutter or large cutter

Weighing Machines

Weighing machines available with wet infeed reception hopper. Computer controlled weighing system with multiple options.

Fruit/ Vegetable filler

Used for filling wide range of whole or cut vegetables (gherkins, mushrooms, baby corns, peas, beans corn kernels etc.) and fruits (cherries, strawberries, plums, olives etc.) into jars or cans. Products fed onto a top vibrating "v"angled distribution deck, which provides even distribution of products onto grooved (for orientation) and angled vibrating table, where guides are mounted.

Blanchers

Blanchers are either steam, hot water operated and it can be automatic or semi-automatic Used in inactivate the enzymes, preserve the color, de aerating etc before pasteurization or canning

Pasteurization tunnels

Used for pasteurization and cooling of products in cans, jars, bottles, plastic bags/trays etc. in six process sections with precise temperature control and minimum energy consumption thru new design regenerative heat recovery system.

Retorts

We can offer you horizontal or vertical retorts it can be pasteurization retort or sterilization retort depends on the application. Also we can offer you counter pressure retorts water spray type. Can be used to sterilize or pasteurize cans, bottles jars, reportable pouches as well as raw products etc. Capacity can be pilot scale up to large scale.