CHOCOLATE PROCESSING

MIXER, REFINER AND CONCHE

The Universal mixer/refiner/conche is a versatile batch machine designed to manufacture chocolate and compounds and fat fillings. The machine consists of a fixed drum-shaped chamber with an inner lining of grooved plate sections made of perlite cast-iron. This grinding chamber is jacketed for pressure less heating or cooling with water. Rotating exchangeable blades made of hardened steel are pressed against the grooved plates resulting in a combined mixing and grinding action. For more details visit www.h-d-m.com

TEMPERING MACHINES

The tempering preserving the innovative features of this machine but significantly enhancing the level of production thanks to the 100 kg tank that will allow for coating in tunnels of widths of up to 600 mm. Screw pump not removable. Easily interchangeable between molding and coating. Temper 100 kg of chocolate in 15 minutes. Direct competitor in hourly production with extremely higher machines

CHOCOLATE MOLDING LINE

Molding line can be used to produce solid or filled chocolate pralines or -bars. The line may be based on the classical three stage molding or be equipped with one-shot depositors. Moreover products can be manufactured with biscuits or wafers simply by installing the relevant modules. Generally the line consists of: mold feeder + mold heater + chocolate depositor + shell forming section + cooling tunnel (1) + filling depositor + cooling tunnel (2) + shell heater + one shot depositor + mold scraper + cooling tunnel (3) + demolding section + product outlet + mold return. Customized configurations are always possible. For more details visit www.h-d-m.com

CHOCOLATE MOLDS

We supply various types of poly carbonate as well as silicon chocolate molds with various dimensions and designs. We can supply the molds with customer designs as well as logos etc, for more details visit www.mfsmoulds.com

AUTOMATIC SPECIAL CHOCOLATE COATED WAFER BISCUIT P

We can supply the complete chocolate depositing system, wafer feeding systems, de-molding and cooling systems from small pilot scale machinery to large scale production plants.

COMPLETE ENROBING LINES

We offer the latest in full and partial coating lines. They come in six mesh widths ranging from 250 to 12000 MM and offer a large range of enrobing possibilities. Our enrobers can enrobe any kind of product, from confectionery products to wafers, biscuits, or other bakery products. The lines can be customized by adding optional components such as pre-bottomers, double enrobing heads, nut sprinklers and string decorators. The lines cooling tunnels can be set to cool products.

CHOCOLATE BAR FORMING LINES

Bar forming lines generally consist of one or more sets of rolls for the forming of caramel and or nougat layers, followed by calibration rolls, nut sprinkler, cooling tunnel, longitudinal cutters, a rope spreader, a guiliotine, discharge belt, followed by a chocolate enrobing line. It is a modular built production line that can be adapted for any sort of multi-layered candy bar containing granola, nougat, caramel, rice crisps and cereals. A wide range of product sizes can be created and this makes this line a versatile piece of production equipment.

CHOCOLATE BAR EXTRUSION LINES

Bar extruder line, consisting of a hopper feeding two ribble rollers that press the mass through the extrusion head, producing a predefined number of ropes which are smoothly deposited onto a transport belt. A nut sprinkler -optional- could be placed over the belt, usually followed by a calibration roller that brings the ropes to the desired thickness. After that the ropes are guided through a cooling tunnel and cut to length by a guillotine. The cut product is collected on a reception belt and can after that be optionally transported to an enrobing line.

CHOCOLATE COATING SYSTEMS

The pan can be swiveled by means of a gear motor from -90 to +90 to the horizontal line. The machine is equipped with a hood for the guidance of supply and exhaust air and connections for a spraying system. The ADE is operated by a graphical display (touch panel) with which the control of the periphery (vessel for the medium, air treatment station, automated spraying) can be realized. For a high degree of automation the system can of course be equipped with a recipe controlling unit.

CHOCOLATE DROP DEPOSITOR

Line allows for the depositing of drops and chips in a variety of weights and shapes, ranging from 0,05 to 3 grams. These type of products are ideal for industrial supply and subsequent melting, for decorating and for use in other products, above all cookies and ice-cream. The line is available in widths from 400-1200 MM. The standard line includes a double jacketed depositor head equipped with temperature control, a regulation system agitator and controlled measuring. The movements of the depositor head are synchronized with the product collection belt. The line furthermore includes a system to lift the belt during the deposit and a vibrating unit enabling diverse drop shapes. After depositing, the drops are immediately conveyed to a cooling tunnel.

VARIOUS CHOCOLATE WRAPPING MACHINES

We supply low speed to high speed wrapping machines for small chocolate drops as well as slabs.

FLOW WRAPPING AND BANDING MACHINES

We offer a new and innovative way to pack chocolate bars, tablets and Neapolitans in a premium look, at the same time ensuring excellent product protection from environmental influences. Consumers can enjoy products with longer shelf lives and improved taste and texture. With excellent performance of up to 600 products a minute.

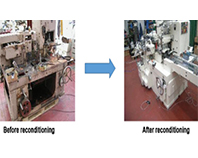

SECOND HAND FULLY REBUILT MACHINES

We can supply almost all the chocolate manufacturing and packaging machinery from European principles based on availability of the machine

SUGAR GRINDERS

We supply state of the art sugar grinding systems for making icing sugar as well as ultra-fine ground sugar based on different applications. For more details visit www.h-d-m.com