EXTRUDED & SNACKS

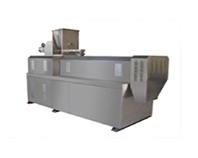

Twin screw Extruder for snacks

This machine is using to extrude the corn grits. This machine contains twin screw, which is moving in a jacketed barrel. The barrel is heated by electric heaters.

Due to the heat and the pressure the product get extrude when it comes out from the die. There is a cutter to cut the product at the die. Due to the shapes of the die and the motion of the cutter different shapes and sizes can be occurred

For more details contact us

Dryer

The output of the Extruder is passing through the dryer to further dry. There are electric heaters to increase temperature and the fans inside the dryer distributes the temperature evenly in the dryer. From this the snacks get completely dry.

For more details contact us

Flavoring drum

This is using to add flavors (eg. Spices ) At the input conveyor of the drum there is oil sprayer, it applies oil to the snacks. At the input of the drum there is sprinkler which distributes salt, spices (powders). Due to the rotation of the drum spices get coted around the snack.

For more details contact us

Air cooler

This is a mesh conveyor, upon the conveyor there are air blowers to cool the snacks

Conditioner

This is using to add water and pre condition the mixture for extruding.

Twin screw extruder

This machine is using to extrude the soya flour mixture. This machine contains twin screw, which is moving in a jacketed barrel. There is nipples to add further water to the barrel. The barrel is heated by electric heaters. Due to the heat and the pressure the product get extrude when it comes out from the die. There is a cutter to cut the product at the die. Due to the shapes of the die and the motion of the cutter different shapes and sizes can be occurred After the extruder the stuff is passing through Dryer and cooling conveyor